The bottom line happens to be the driving force for any business. However, another important aspect of doing business is promoting your product or service. The more people know and recognize you, the more the chances of success. To this effect, businesses go ahead and invest millions in their marketing strategies. And, without a doubt, the benefits ring in sooner or later.

One of the leading dilemmas that business managers suffer from these days is when to spend and when to save. After all, spending every dime of your profit on marketing efforts can never be a prudent thing to do. This dilemma often leads to managers trying to cut corners and save on whatever they can. However, there happens to be a fine line between skimping, spending and investing.

When it comes to getting logos digitized for the first time, decision makers know that they are making the right choice and have no doubt whether to spend or save. However, when it comes to re-digitizing the same logo or design when a few elements have changed, they tend to wonder whether it’ll be considered as wise spending or splurging.

The following are the most common examples of when you’ll need to call for fresh embroidery digitizing for the same design along with the reasoning that’ll help you decide for yourself whether it turns out to be a waste or an investment:

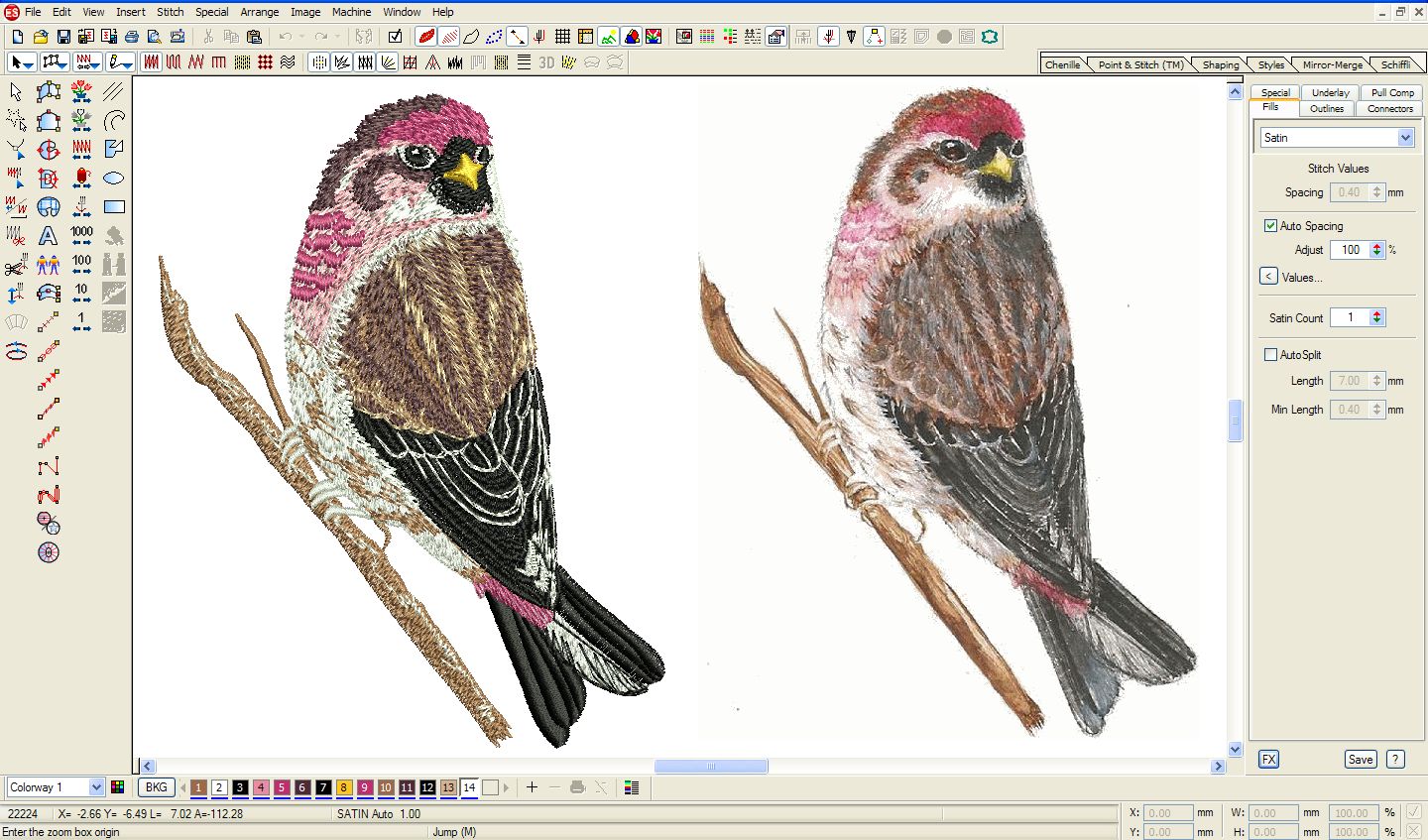

Scaling – One of the primary reasons you would need to head back to your embroidery digitizing professional is when you need to shrink or enlarge your logo or design. While you might think this to be an easy task that can be taken care of with simple adjustments in the software, it actually happens to be a lot more complex. This is because your digitizer will need to look at the design afresh and see how a change in size will affect the type of stitches used, stitch length, stitch count, sewing strategy, push/pull compensation and even that the design doesn’t end up with gaps due to insufficient stitches. Also, if it is a 3D puff design or one with special effects, digitizing afresh becomes all the more essential. A simple change in the angle of the design too could require re-digitization.

Change of Fabric – So you’ve decided to upgrade your employee uniform or promotional giveaways from thick polyester to comfortable cotton or regular fleece to haute leather. Going to your embroiderer with the old digitized files for your logo will be a big mistake, as different fabrics register designs very differently. You could not only end up with ruined garments and poor embroidery, but also disrupted production runs which could add to your bill with damaged needles, frequent thread breaks and even jammed machinery.

Change of Garment Type – You love how that logo sits on the t-shirt and want to replicate it on baseball caps. You’re wondering whether you can get away with the program used on your t-shirts, as they’re both 100% cotton. The answer here would be “no”. Embroidery digitizing for a shirt, cap, bag or even jacket for that matter is very different as their respective surfaces are very diverse. While shirts are flat, caps and circular in shape, thus requiring a completely different set of skills and instructions. Again, lost production time and ruined fabric can pile up the losses.

At Powerstitch.com, we offer expert embroidery digitizing services for picture perfect registration and smooth production runs for all your design needs. With over 8 years of professional expertise, you can count on us for impeccably digitized artwork at the most competitive rates, delivered on time, each time.